Digitalized inspection and data management platform

Benefits for business

- Improve efficiency and reduce costs: Digitalized inspection greatly improves the efficiency of all kinds of quality inspections, meanwhile,it make data sharing and access very convenient;

- Unified database: Stores data helpful for quality monitoring, analysis, improvement, forecasting and management in a unified database, eliminating data isolation;

- Ensure data authenticity: Minimize human data errors and ensure data authenticity and reliability;

- Improve quality traceability: data is integrated with a certain logic to help trace quality issues;

- Data security: Avoid unauthorized access to data

Sampling management

The system can not only collect a variety of data, but also help you carry out sample inspections on demand:

- Sampling by time or event;

- AQL、LTPD、MIL-150: help users to automatically complete sample inspection by batch according to relevant standards;

- Random sampling: Built-in random algorithm helps users to randomly sample data from a specified data source;

- Custom sampling method: Obtain data from specified data sources according to custom sampling rules;

See "Sample Inspection Specification Example" .

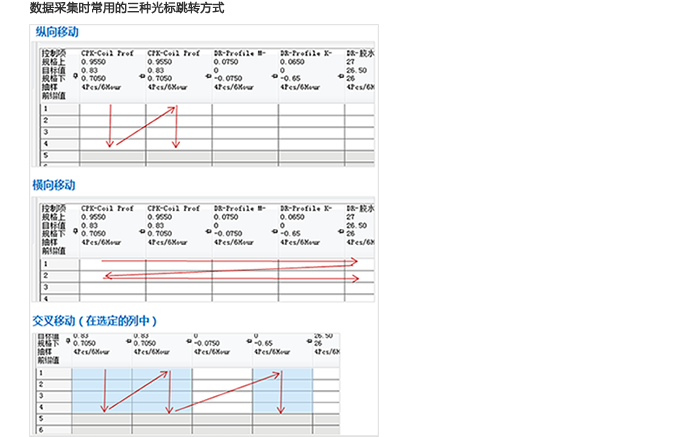

Data Collection approaches

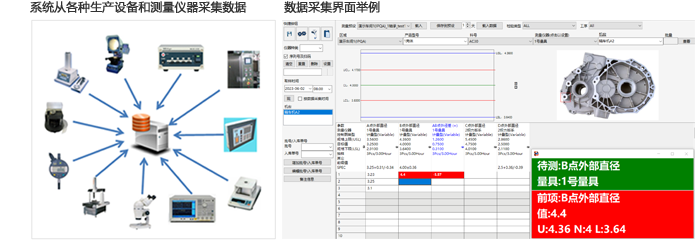

The system's built-in instrument library can easily collect data from various brands of measuring instruments; meanwhile, it supports custom data collection methods that meet user habits, making the measurement and data collection process leane and efficient:

- Extensive support for collecting data from various instruments and equipments: The platform supports collecting data from various brands and various types of measurement meanings, with strong compatibility and high efficiency. The instrument library built-in helps users to communicate with instruments and equipments with very simple settings;

- Supports variable and attribute data collection: The platform supports both variable and attribute data collection in efficient ways;

- Extensive communication interface: it can automatically obtain data from other systems on demand and integrate data according to requirements;

>>View function and feature list

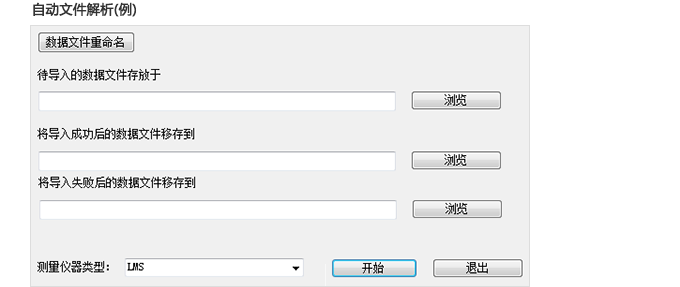

- Parse data file: The platform can obtain data from various kinds of data files, once the system's automatic file parsing function is turned on, you only need to place the data files in the specified folder, and all other subsequent work will be done silently for you. Many times, you don't even need to "put the data files under the specified folder".

>>View function and feature list

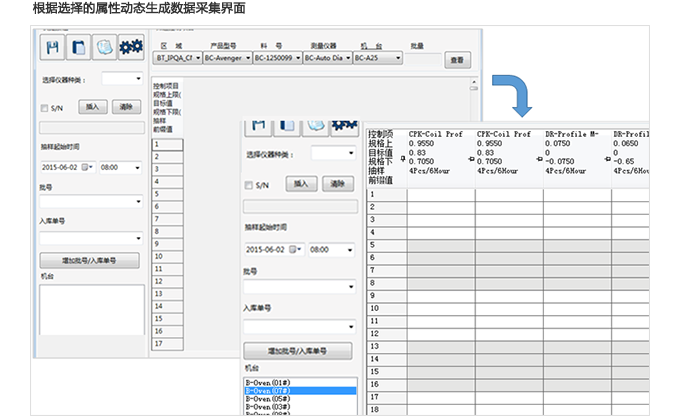

Flexible and powerful customization capabilities

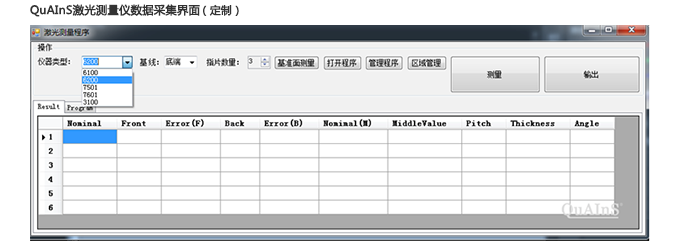

For specific instruments and equipments, the measurement interface and data conversion functions can be flexibly customized according to the measurement needs.

>>View function and feature list

Data security and use

- Equipment status monitoring: When the production equipment and measuring instruments in the system are in "maintenance" state or deemed unqualify, the system automatically refuses to collect data to ensure reliable data quality

- Control access to data: For example, frontline inspectors usually only have the authority to input and query data; only authorized users can correct data errors, etc., thereby ensuring that critical quality information can only be accessed by right people at right time. >> Reference permission settings

- Convenient data use: Under a good authority control mechanism, different users can easily query, correct errors, import, export, sort and do other operations on data.

>>View function and feature list

This platform, together with other sub-systems of QuAInS® , form a complete closed-loop, scientificly designed system architecture.