Quality big data analysis platform

This system provides customers with a "one-stop" platform for quality analysis, experiments, quality improvement and management. It not only can perform standardized "one-click" quality analysis but also can help senior engineers, Six Sigma green belts, black belts and MBBs to perform interactive analysis efficiently, the analysis results are trusted to be consistent with famous industrial statistical analysis software.

What is standardized analysis and interactive analysis

In daily work, it is not enough to only have a static quality report. We also need to conduct deeper analysis to get insight to quality issues. However, other professional statistical analysis software with comprehensive functions, flexible and complicated methods is usually very unfriendly for the common engineer: though they spent a lot of time participating in various trainings, but they usually still don’t know how to perform an analysis right fitting them?

The key is in analysis ideas, not in the method itself!

Fortunately, quality experts (such as Six Sigma Black Belt, Master Black Belt Master, etc.), who usually have deep understanding of the situation, can help to establish analysis ideas and standardized process based on their knowledge and experience. And then junior and agerage engineers only need to follow them to finish analysis easily.

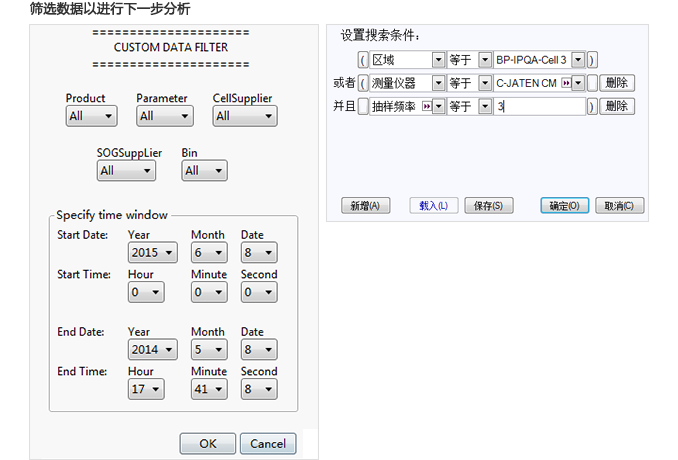

Dispite of such "standardized" analysis process, junior and average engineers still need certain flexibility: they can also have their own inputs into the process - interactivity(interactive analysis)

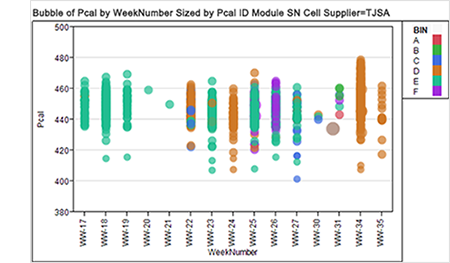

For example, the engineer may firstly need to analyze the yield difference of different Lots, and then select to analyze the distribution of Lots with poor yields by different production equipment, or select to analyze possible sources of variation of Lots with poor yields, or select to analyze the correlation of some parameters, etc

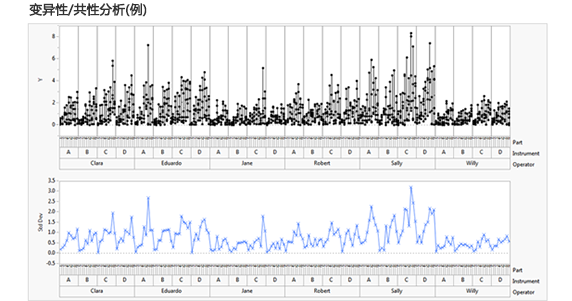

The practice of statistical quality management shows that in order to obtain applicable process and quality improvement programs and predict their risks, senior process and quality personnel need to comprehensively utilize various feasible intelligent analysis methods, and they have even higher requirements for interactive analysis.

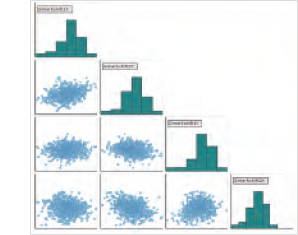

They may need to use exploratory analysis methods to find opportunities and spaces for improvement, use hypothesis testing, correlation analysis, regression, stepwise regression, LASSO, screening methods, and more advanced data mining methods to lock on key factors and be aware to the existence of multiple collinearity; they often need to carefully design experiments to collect reliable information about the process at the lowest experimental cost, and may also need to rely on reliable models to optimize process parameters, and to effectively predict improvement effect and risk through reasonable methods.

What QuAInS can do for you

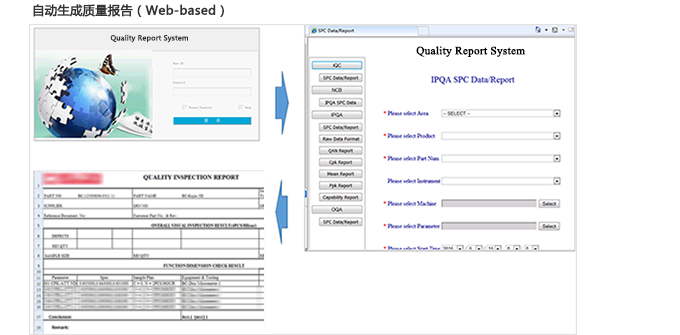

At the most basic level, QuAInS can automatically generate various Excel format reports (such as incoming inspection report, quality inspection report, shipment quality report, etc.) according to the template you created. This will significantly reduce the time it takes to provide customers with quality reports and reduce the chance of errors.

In addition, the system can also automatically generate various analysis reports, and then present them in a visual way, so that you can easily browse through a computer, tablet, network, etc., wherever there is a network. >> Learn more about analytics and reporting automation

Furthermore, we can help you automate your analysis when you need to do some in-depth analysis of your data . Many times, you don't even need to buy a new software, but simply dig deep into the capabilities of existing analysis software.

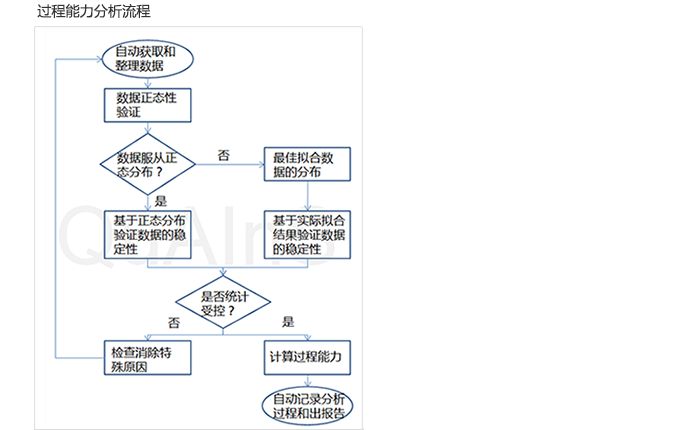

For example, process capability analysis (Capability Analysis) needs steps of automatic acquisition and cleaning of data, verification of the normality and the stability of data, automatic fitting of the best distribution, specifing specification limits, automatic calculation and generation of reports. The engineer will be guided to complete the analysis following the established analytical process.

And if you do not know how to analyze the data in order to be practically useful, QuAInS quality big data technology consulting services will help. Our industrial statistics consultants will analyze and solve practical problems with customers, and provide professional consultancy for your quality big data strategy, data integration, analysis method selection and so on; At the same time, the system engineer will assist in developing these feasible ideas into analysis automation programs and train the engineers to analyze according to the ideas. The final deliverables include both the financial benefits of solving specific problems and a set of standardized quality analysis procedures tailored to the actual situation.

Interactive analysis and prediction: As we all know, there is no formula for interactive analysis, and there are often more than one feasible methods and cross-validation may be required between them. The system can help senior process R&D and quality improvement personnel to achieve the this well, and ultimately help the company to improve the quality with the highest efficiency and the lowest cost. At the same time, good models can help us effectively predict the quality status of future products and know what to do next.

>> Welcome to contact us to know more

This platform, together with other sub-systems of QuAInS® , form a complete closed-loop, scientificly designed system architecture.